MAIN PRODUCTS

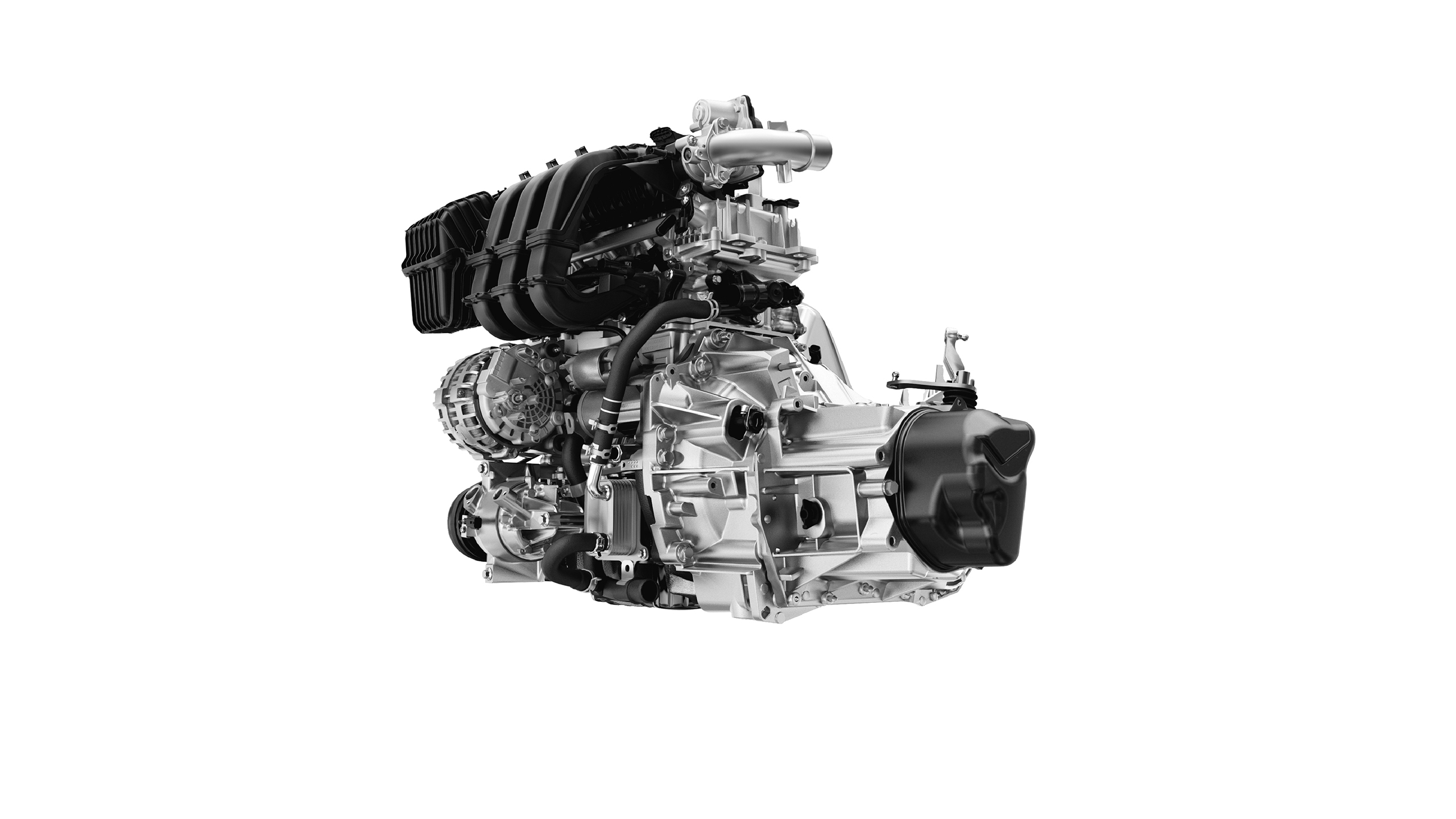

- Engines: BR10, HR16 Gen2, HR 16 Gen3 Hybrid

- Gearboxes: JR, JH

- Foundry: Aluminium (HR16 Gen3 cylinder block casting)

PRODUCTION (2022)

- Gearboxes: 113,170 units

- Engines: 160,028 units

- Aluminium foundry: 93,000 units

Thank you for visiting us. We are now part of Horse Powertrain – a new global leader in powertrain technology – and are currently merging websites. For the latest information, updates, please visit us at www.horse-powertrain.com.

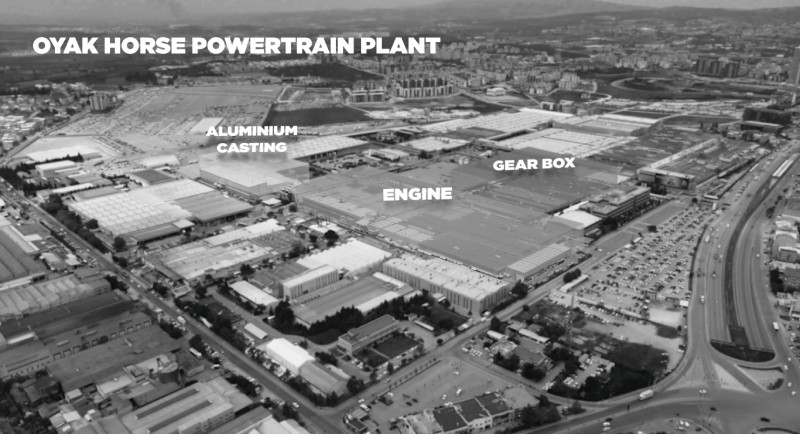

The powertrain plant in Bursa, which was part of Oyak Renault until recently, is now OYAK HORSE, a new company set up under a partnership between Oyak and HORSE Holding.

The plant was built in 1970 and has manufactured over 7 million engines and 6 million gearboxes for domestic and export markets over the past 53 years.

OYAK HORSE encompasses a high-pressure aluminium injection facility, engine and gearbox department, and R&D Centre. This new partnership will open the door to fresh investment in low-emissions engine production in Türkiye.

FOUNDED IN: 1969

LEGAL FORM AND CAPITAL OWNERSHIP: Société Anonyme (limited company), a partnership between OYAK and HORSE Holding

ACTIVITY: Powertrains, high-pressure aluminium injection, engines and gearboxes

R&D: The Turkish R&D Centre’s experienced team uses its three engine test benches and its static test cell to develop naturally-aspirated petrol engines for internal-combustion engines and hybrid powertrains.

WORKFORCE: 875 people at 1 July 2023

AREA: 8.1 ha

CERTIFICATIONS: ISO 9001, ISO 14001, ISO 27001

The OYAK HORSE plant has earned ISO 14001 certification and is committed to continuously reducing and ultimately avoiding its environmental footprint and the health impact associated with its operation, as per Renault Group’s environmental policy. The Bursa plant’s employees, and all other company employees, apply the environmental management system.

OYAK HORSE’s workplace-safety and customer-satisfaction policy is aimed at “Zero Accidents, Zero Faults”. We consistently achieve our quality targets to keep our customers satisfied despite the increasingly stringent requirements and constant changes in the technological and regulatory landscapes.

Our performance at a glance

By August 2023, the OYAK HORSE plant had produced 7,308,920 engines and 6,035,710 gearboxes.

One engine rolls off the production line every 50 seconds, and one gearbox every 56 seconds.

The foundry melts 6,400 tonnes of aluminium a year.

The OYAK HORSE Bursa plant has been entrusted with the next-generation HR18 hybrid powertrain.

1969: Oyak-Renault was founded (44% Renault, 43% Oyak, 13% Yapi Kredi).

1970: The Bursa plant was built.

2010: Produced its 3,000,000th gearbox.

2011: Produced its 3,000,000th engine.

2014/2015: Bursa reached its 4 million gearbox and 4 million engine milestones.

2017: Produced an all-time-high 599,318 engines.

2018: Renault Group signed a new agreement with Oyak to extend its solid, long-term partnership for another 27 years, on 29 June.

2019: Celebrated its 50th anniversary, inaugurated the aluminium injection foundry, produced its 6,000,000th engine.

2020: Started manufacturing the HR16 Gen3 hybrid engine.

2021: 7,000,000th engine.

2023: The OYAK HORSE Bursa plant and foundry became part of HORSE on 1 July.

OYAK HORSE

Makine Ekipmanları Ticaret ve Sanayi A.Ş

Balat OSB Mah. Mavi Cad. 5. Sokak No :1

16372 Nilüfer / Bursa Türkiye

Tel: +90 224 219 45 00